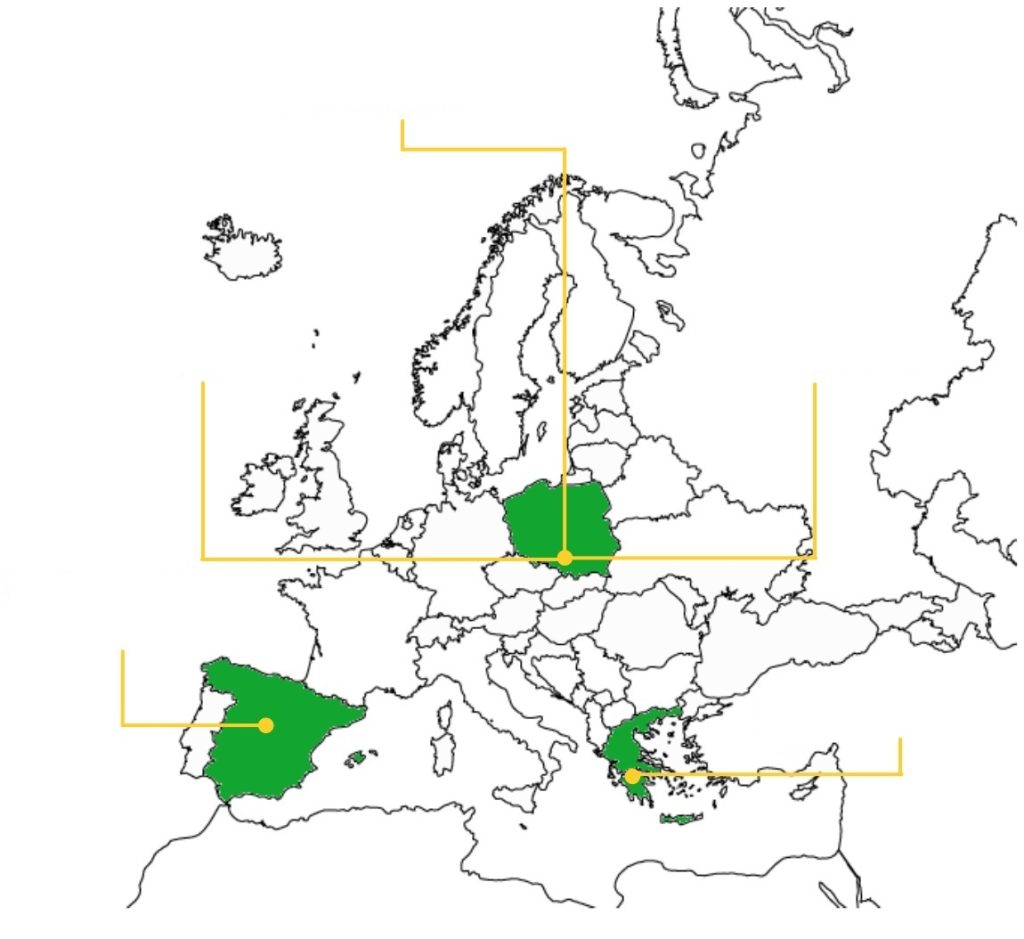

The Waste2CRM project consortium is an international collaboration of six experienced organizations, each bringing specialized expertise to different aspects of the project. They represent a balanced mix of research institutions, industry, and academia, ensuring a comprehensive approach to CRM recovery from coal mining waste. The partners are:

INSTYTUT TECHNOLOGII PALIW I ENERGII – Institute of Energy and Fuel Processing Technology (ITPE, Poland): The project coordinator, ITPE is a research institute with extensive experience in energy and fuel processing technologies, waste management, and environmental protection. Their role encompasses overall project management, coordination, and dissemination of results.

GLOWNY INSTYTUT GORNICTWA – Central Mining Institute (GIG PIB, Poland): A leading coal mining research institute in Poland, GIG brings in-depth knowledge of coal mining practices, waste characteristics, and environmental monitoring. Their primary contribution focuses on sampling, analysis of mining waste, and environmental impact assessments.

In essence, the consortium combines academic research capabilities, industrial expertise, and practical experience to address all stages of the proposed CRM recovery process from coal mining waste, ensuring a comprehensive and effective project implementation.